|

build log |

|||||||

|

|

|

|

|

||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

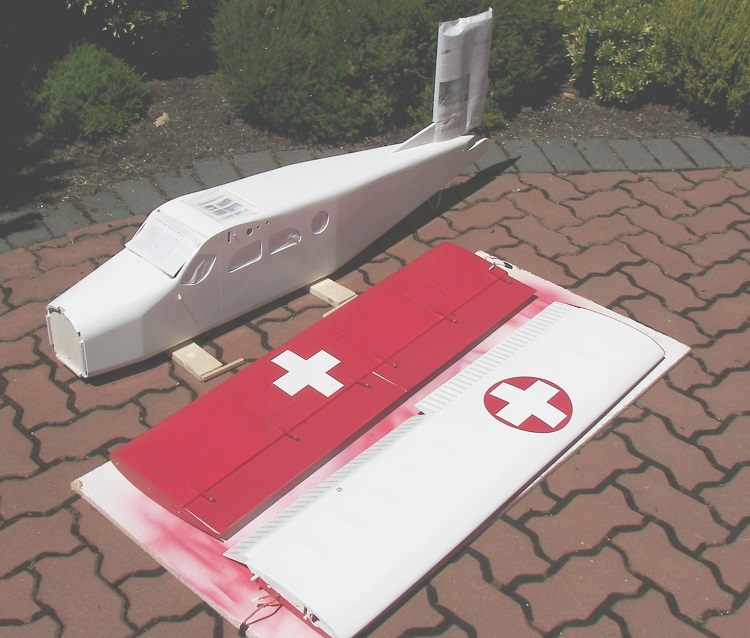

.....definitely starting to look like a Porter!!

The little round bubble windows were made by heating a sheet of PETG plastic with a heat gun and pressing it over a balsa mould, they will go into the cabin area after covering.

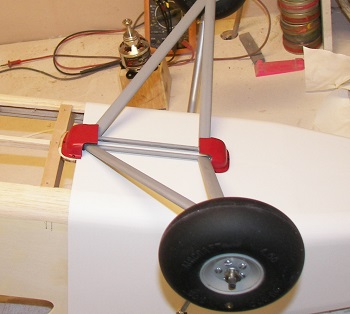

Landing gear and oleo struts are roughed out and ready to install.

Here the cowl is started.....A foam plug was first carved, covered with epoxy and sanded smooth. The plug is set into a wood box, waxed and coated with PVA and laid up with four layers of fiberglass. This will form a two-piece female mould.

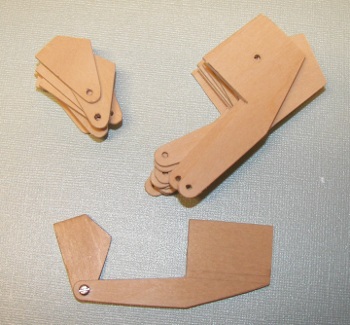

Here is the finished cowl and the red vacume-formed covers for the landing gear hinges.

Covering and finishing has started......Here are the tailfeathers with three coats of latex sprayed on and some waterslide decals applied. A coat of nelson's flat clearcoat seals everything in. The decals, including the corrugations on the elevator are waterslide and made on my computer.

Here is the motor installation....we will try an E-Flight 60 for starters with a four-cell 5000 battery Here the first coats of paint are going on the fuse and wings.

| |||||||

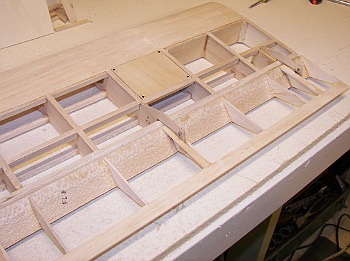

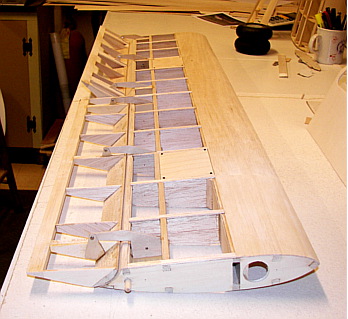

The wing is of

standard construction.....nothing new here.

The wing is of

standard construction.....nothing new here.