|

Consolidated PBY Catalina

build log

|

||||

|

|

go to..... |

|

|

|

|

|

||||

|

|

||||

|

Here the fuselage is started on the workbench.....It will be built upside-down and turned over when it is sheeted. I expect to use twin electric motors in the same size that I used in the twin Otter....it was about the same size and weight.

The tailfeathers are framed up and covered with Solartex. Now to figure out some way to blend the vertical fin into the fuselage.....it needs to be a compound curve. The elevator is operated with a single servo up front and a carbon pushrod operating through a bell-crank and up to the elevator..

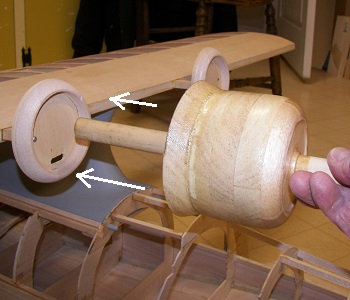

Making the cowling.....We need to laminate five pieces of 3/4" balsa together to make the cowl. I have cut the circular pieces on the bandsaw using a jig to cut perfect circles. The jig can be set at different diameters and angles. The laminated block is then shaped in the lathe using my dremel as a cutter. A very smoothe finish results.

Here is the wooden plug which

will be used to make the two fibreglass cowls it needs to be smoothed and

primed before it is used to make a mould. The cowlings will fit in front of

the nacells which are being formed on the wings.

Here are the cowls.....ready for paint.

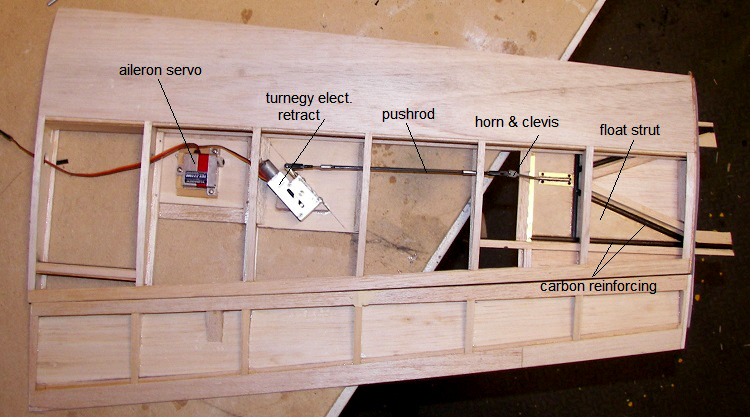

Here the operation of the wingtip floats can be seen.....Instead of a servo to operate the wingtip floats I used a small electric retract unit and a pushrod. The floats retract quite slowly and scale-like and they lock in the up and down positions. The aileron servos and the float activators are accessed by doors on the bottom of the wing.

|

||||

|

|

||||