|

|

|||||

|

|

I would like

to give special thanks to Mr. Luis Jove in Asturias, Spain who has given

me a great deal of data and advice on the construction and documentation

of the Hansa Brandenburg. |

|

|||

|

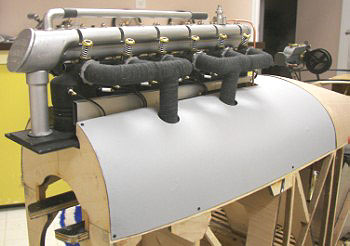

June 14 The dummy engine is started, scratch built from bits and pieces found around the shop. It sits way up out of the cowl. The cylinders were cast in resin using a rubber mould system. the rocker arms and sparkplugs will be done the same way. |

|||||

|

|

|

||||

|

The upper portion of the cowl is

a compound curved surface and difficult to sheet.....also I wanted it to

be removable for access to the engine so I made it of fiberglass. A

separate frame was made identical to the frame of the model and the spaces filled with foam. A couple of coats of glasscloth and the new cowl is complete. |

|||||

|

|

The engine front plate was made by photo-engraving onto a brass plate, this was done by Luis Jove in Spain and given to me as a gift, very much like the original. |

||||

|

|

|||||

|

|

|||||

|

|

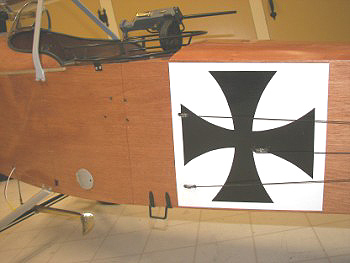

Landing

gear is now complete with rigging and the landing sprag has been attached

to the axel. |

||||

|

October 20th. |

|||||

|

|||||

|

November 15th. Now the fuse is fully sheeted and finished with stain and varnish. The engine and electrics are installed, and a lot of small details have been completed. The footsteps were fabricated out of styrene. The pull-pull cables to the tailfeathers are kevlar. The door in the cowl will stay open for air outlet from the engine compartment. The inspection panels were vacum-formed of styrene. What cannot be seen in these photos is the dozens of small brass brads along the joins in the plywood. The cabane struts and radiator are in place. Just a few more details and the fuse will be ready for the wings. |

|||||

|

|||||

|

Now back to the wings.... |

|

||||

|

|

|||||

|

The above shots show the Hitec thin wing servo installed in the lower wing and operating a hidden bellcrank. kevlar pull-pull chord goes along the lower wing, around two sets of pulleys and to the ailerons on the top wing.....complicated but that's the way it was !! The servo and bellcrank are mounted on the inner side of a door which opens from the outside. I have room for a second servo if the one is not strong enough. |

|||||

| Here's where the pull-pull ends up on the top wing..... | Here on the lower wing you can see the rib stitching, the aileron pull-pull exits, the pulleys and the strut attachments..... | ||||

|

|

|

||||

|

Strut attachments are anchored into the spars.

|

|||||

|

|

|||||

|

|

|||||